Industrial computer repairs

Many industrial computers are simply used as 'controllers' for large factory machines. In fact, this applies to almost any machine requiring automated management. No matter how complex, it is only the software that is special to that environment. Just because they are specially made, it doesn’t mean that they are impossible to repair.

DataReco has designed many modifications to address these problems - as long as there is an image of the data, we can work around the problem and find a solution.

Some Other Specialty Modifications

Factory Machines often have out-of-date PC controllers, and when there is a problem with a PC controller, it is thought to be redundant or too difficult to modify. At DataReco, we can often update or upgrade the controller to get your systems working again.

So called 'old Motherboards' are still otherwise important in some special tasks as they are often part of a big machine that is irreplaceable economically. Here are some of the situations we have been able to provide solutions for:

Example 1:

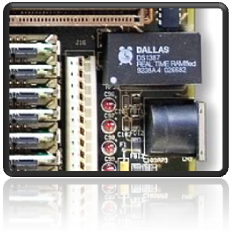

The Dallas RTC chip renders a motherboard useless after it expires. That RTC chip has a tiny hidden battery embedded into it, and is not replaceable. The life expectancy is said to be about 10 years, after that the motherboard is dead. However, in some cases the chip can be replaced. Be aware of chips that are unused but still 10 years old - the battery may already have run down. So usually, if replacing the chip is not safe or date-sure, then modifications can be done. The chip can have two holes drilled into it, to expose the circuit for external power.

The Dallas RTC chip renders a motherboard useless after it expires. That RTC chip has a tiny hidden battery embedded into it, and is not replaceable. The life expectancy is said to be about 10 years, after that the motherboard is dead. However, in some cases the chip can be replaced. Be aware of chips that are unused but still 10 years old - the battery may already have run down. So usually, if replacing the chip is not safe or date-sure, then modifications can be done. The chip can have two holes drilled into it, to expose the circuit for external power.

Example 2:

Early Factory Machines are still actively involved in many roles, such as management of kitchen and cabinet making, cutting, medical, diagnosis, conveyor belts, sorting, agriculture, engineering bending and cutting, etc. The Industrial Machine may not date, but the PC-controller may become unserviceable. In particular, for this example, the Monitor or Display, is one to fail, or be too blurry.

Converting Displays on CNC machines which have MONO TTL or CGA monitors.

The old Monitors are often MGA or CGA or EGA and those monitors are obsolete. So conversion from the 9-pin RS-232 TTL mono video-out connector is not easy, to adapt the video signal to support a modern VGA or LCD display panel. It's not just an adaptor; there are H and V signals to process the digital to analogue. At DataReco, we have designed 5 different solutions to suit most scenarios. This will enable the installation of LCD display panel into early CRT environments.

The old Monitors are often MGA or CGA or EGA and those monitors are obsolete. So conversion from the 9-pin RS-232 TTL mono video-out connector is not easy, to adapt the video signal to support a modern VGA or LCD display panel. It's not just an adaptor; there are H and V signals to process the digital to analogue. At DataReco, we have designed 5 different solutions to suit most scenarios. This will enable the installation of LCD display panel into early CRT environments.